GIFAD

Reveal your delicates surfaces

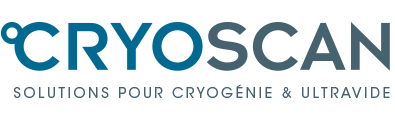

based on He atom diffraction, the new probe GIFAD (Grazing Incidence Fast Atom Diffraction) is an ideal tool for structure investigation of organic films and semi conducting or insulating surfaces.

Développed at the Institut des Sciences Moléculaires d’Orsay (ISMO) et patented by the CNRS and Université Paris-Saclay, the GIFAD method (Grazing Incidence Fast Atom Diffraction) is a new probe of the structural properties of solids, strictly non destructive and with an extreme sensitivity to the surface (no penetration at all). Based on the coherent scattering of a neutral He beam this method is complementary to the Grazing Incidence Surface X ray Diffraction (SXRD) and the RHEED. The method is perfectly adapted to the insulating surfaces and electron sensitive surfaces, like organic films or complex oxyde surfaces like perovskytes for instance.

The grazing incidence geometry allows a real time study during deposition of thin films giving information about the growth mode or phase transitions or structural re arrangement. High pressure GIFAD is under development to make the method compatible with high pressure sputtering method of synthesis.

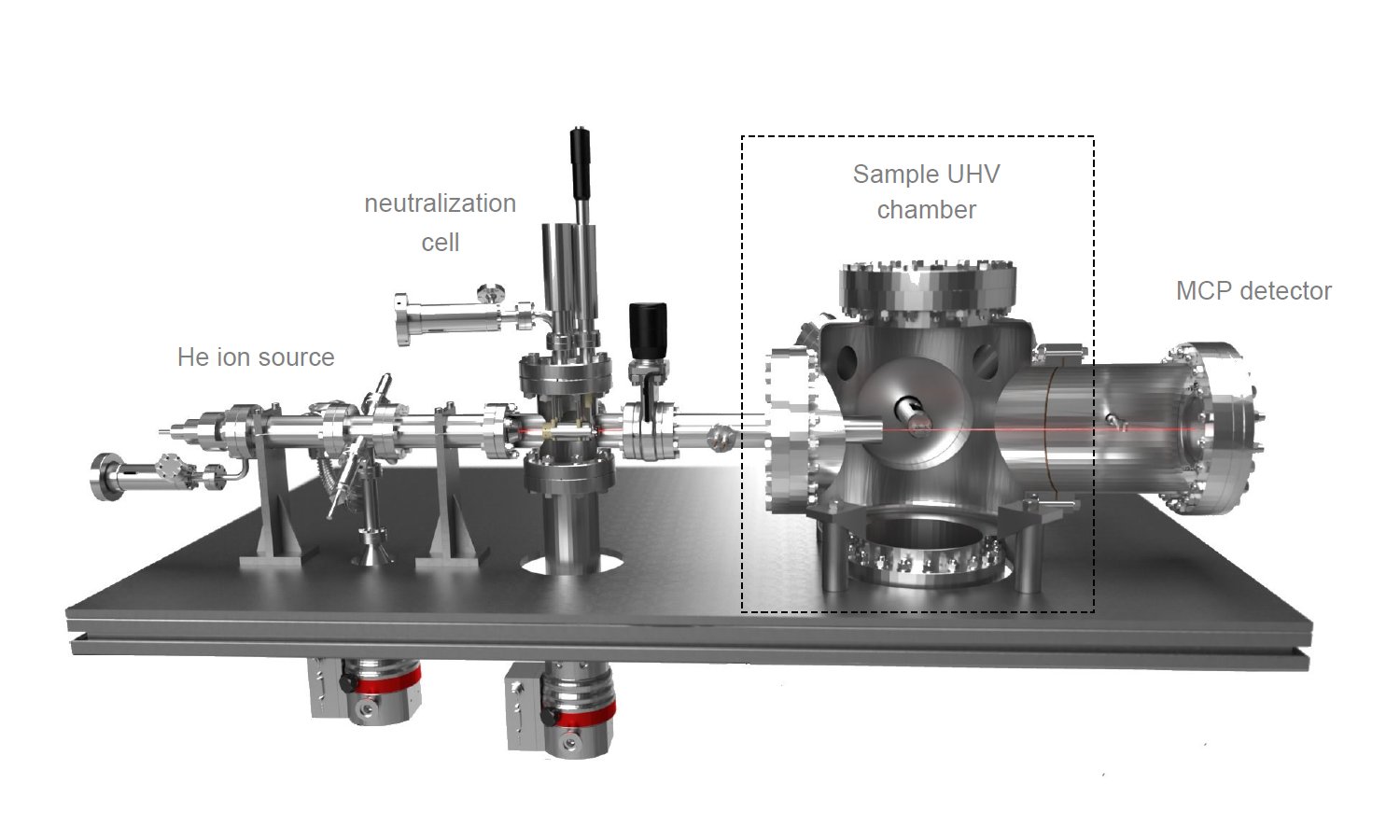

Fitting a GIFAD device on an existing UHV chamber is possible if two flanges (CF 40 and CF 100) exist with in line configuration (180°). An in plane sample rotation is also needed. The incident angle (< 5°) can be obtained with the sample support or by an optional tilt mechanism of the ion source.

THe main technical specs of our GIFAD set are given below. Custom solution can be studied on request.

| Fitting | He source: 40 CF Flange/ Detector : 100 CF flange | ||

| sample type | metallic semi conductive or insulating single crystal surface | ||

| working pressure | 2. 10 -9 mbar (10-6 under development) | ||

| He+ source pressure | 5. 10 -4 mbar | ||

| detector technology | Double Micro Channel Plate (MCP) + CCD camera | ||

| length of He source | L = 650 mm | ||

| Baking temperature | 150°C | ||

| UHV chamber pumping seed needed | 300 L/s minimum with turbo pump (noble gaz pumping) | ||

| Differential pumping of the He line | He+ source : turbo pump 70 L/s – neutralization cell : turbo pump 70 L/s | ||

| Length of detector | L = 200 mm | ||

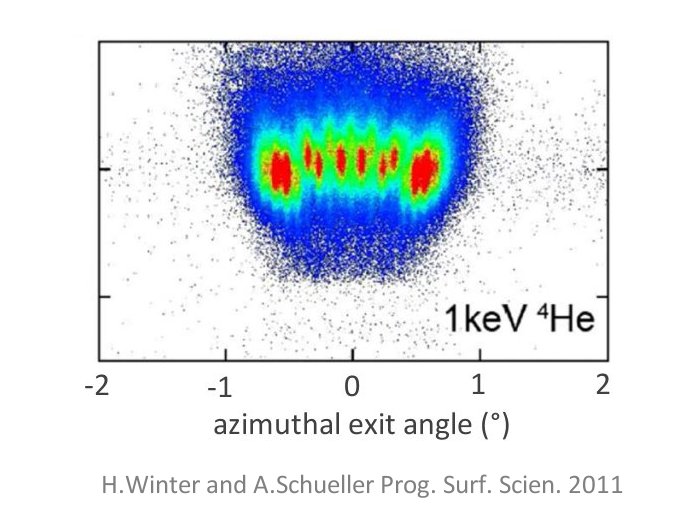

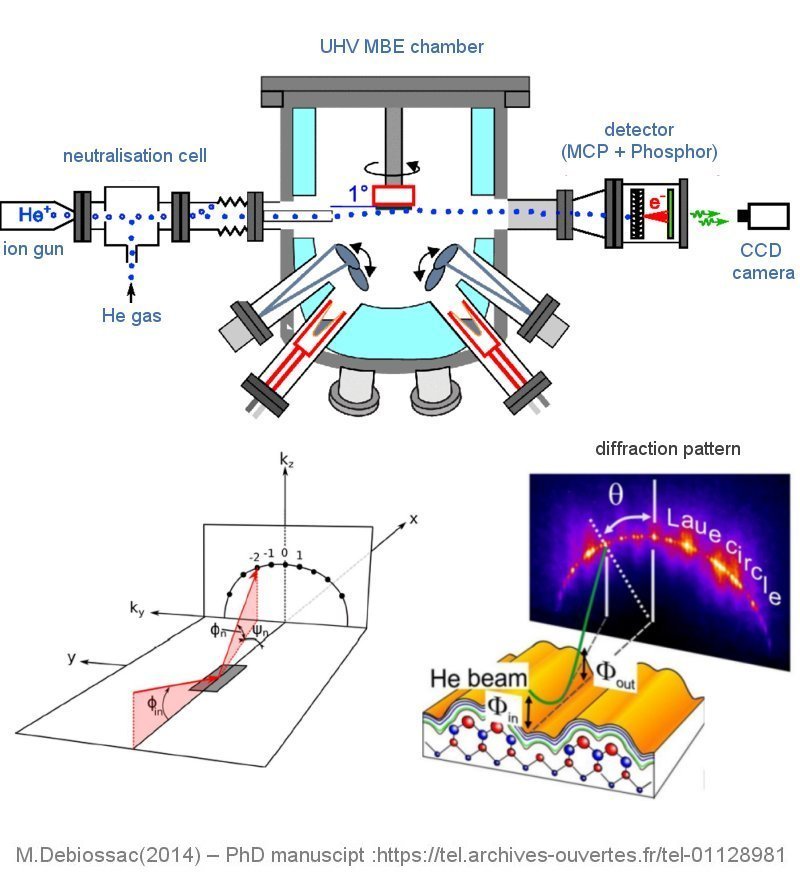

GIFAD is based on the coherent scattering of a neutral helium atom beam produced from an He ion source then neutralized from interaction with He gaz in a neutralization cell. The detection of the diffracted atoms is done by a double micro channel plate (MCP) and a phosphorescent screen recorded by a standart CCD camera. The energy of the atomic beam ranges fromfew hundred eV to several keV.

The weak incident energy normal to the surface (few meV) and the repulsive interaction between incident He atoms and the crystal surface makes this method strictly surface sensitive in contrary to the electron diffraction methods (LEED or RHEED) or Surface X ray Diffraction. This interaction is sensitive to the corrugation of the surface electron density (averaged in the beam direction). The resulting diffraction pattern shows therefore an intensity distribution along the diffracted orders which is dependent of the fine corrugations of the interaction potential along the direction normal to the incident beam. It is therefore possible to distinguish crystallographic directions which are almost similar in RHEED patterns. The nature of the interaction potential makes possible the quantitative simulation of the diffracted patterns leading to the atomic structure resolution. Thank’s to the low energy of the neutral He atoms the method is fully non destructive.

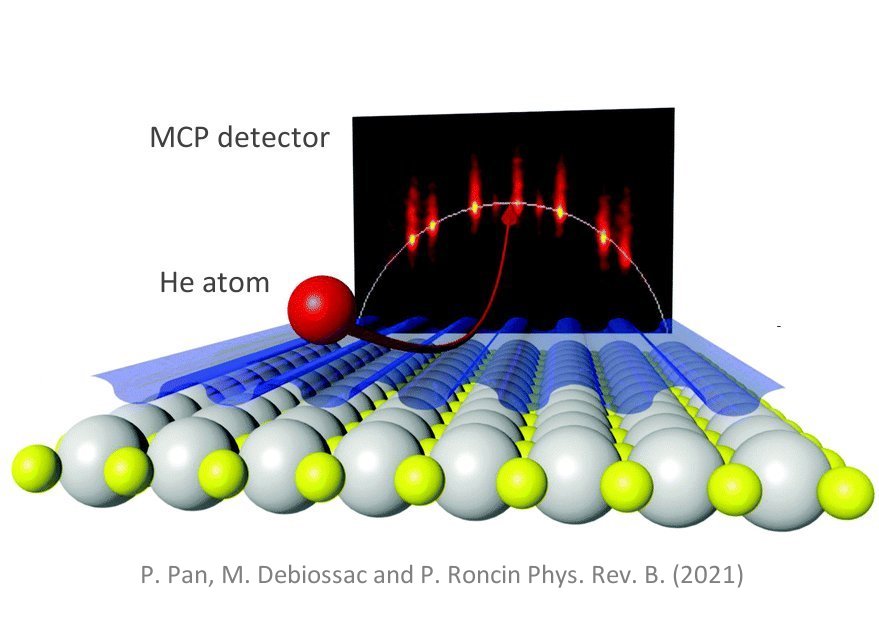

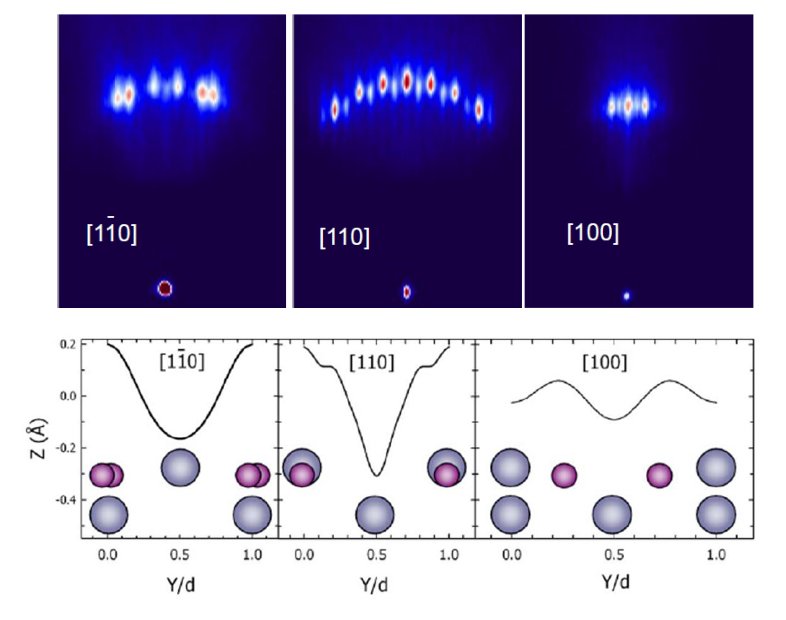

ZnSe(001) single crystal

GIFAD patterns recorded for 3 azimuts of the surface and with an energy of the incident beam of 400 eV.

The directions [110] and [1-10] which are equivalent on RHEED patterns because of the 4 fold symmetry of the surface show with GIFAD very different intensity distribution on diffraction orders. This is the consequence of the very different corrugations of the interaction potential in the direction normal to those azimuts

The bottom figure sketch, for the 3 azimuts, the positions of the Zn and Se atoms in the unit cell along the normal direction of the incident beam and the resulting corrugations of the interaction potential. [H.Kehmliche,P. Roncin et al – APL 95 (2009)]

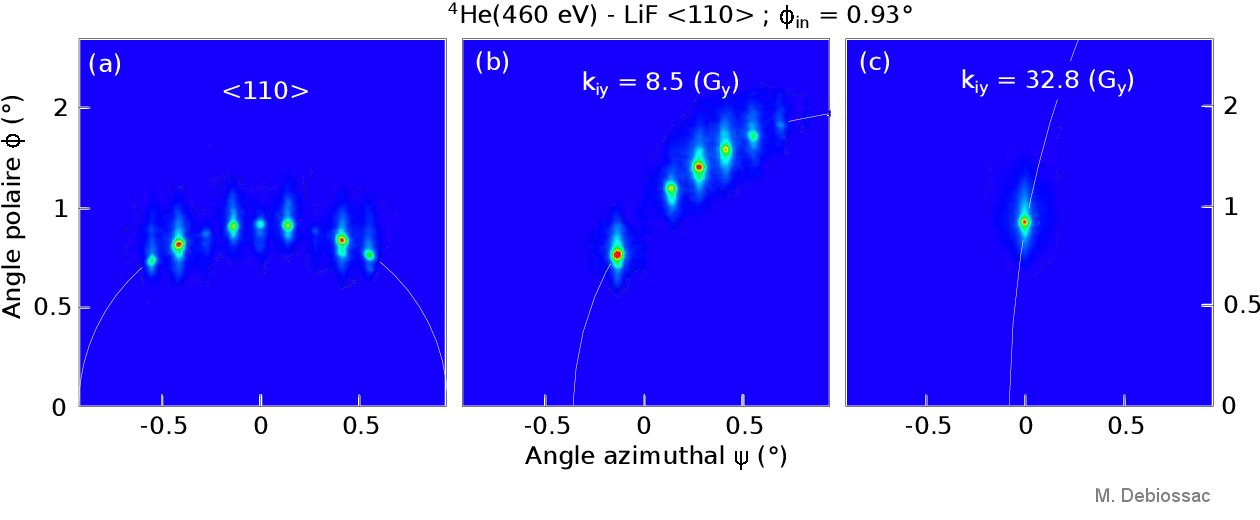

Helium diffraction on an insulating LiF surface

GIFAD patterns recorded for He beam along the [110] atomic row of a LiF crystal and for a sligthly of axis direction (middle) and far from the azimut. In the latter case the averaged interaction potential mimic a perfectly flat surface making visible only the zero order (specular reflection).[M.Debiossac(2014) – PhD manuscipt :https://tel.archives-ouvertes.fr/tel-01128981].

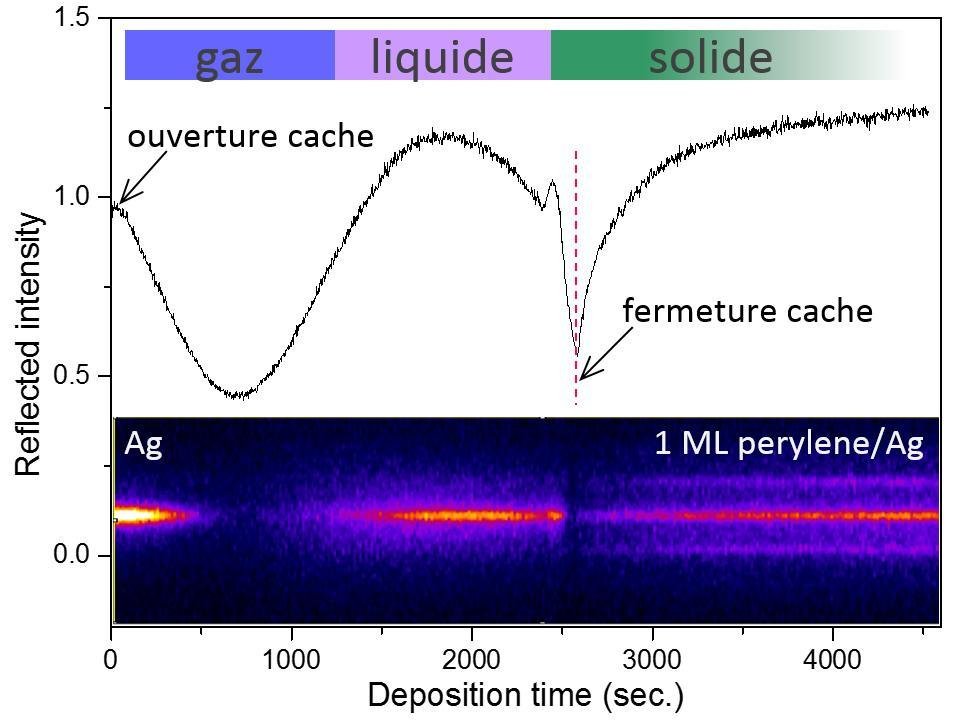

Time evolution of the GIFAD pattern during perylene deposition on Ag(001) single crystal

Specular intensity (middle) and cross section of the GIFAD pattern (bottom) vs time, recorded during the deposition of perylene on Ag(001) single crystal. In the early stage a disordered and corrugated « gas phase » covers the surface and leads to the lost of the diffraction spots. Then for higher coverage, a liquid and flat phase start to develop and the specular spot is recovered. Finally after stopping the deposition and for almost 1 ML coverage an ordered solid phase is obtained and a multiple order diffraction pattern is visible [ Adapted from Momeni A et al – J. Phys. Chem. Lett.9 (2018) 908].

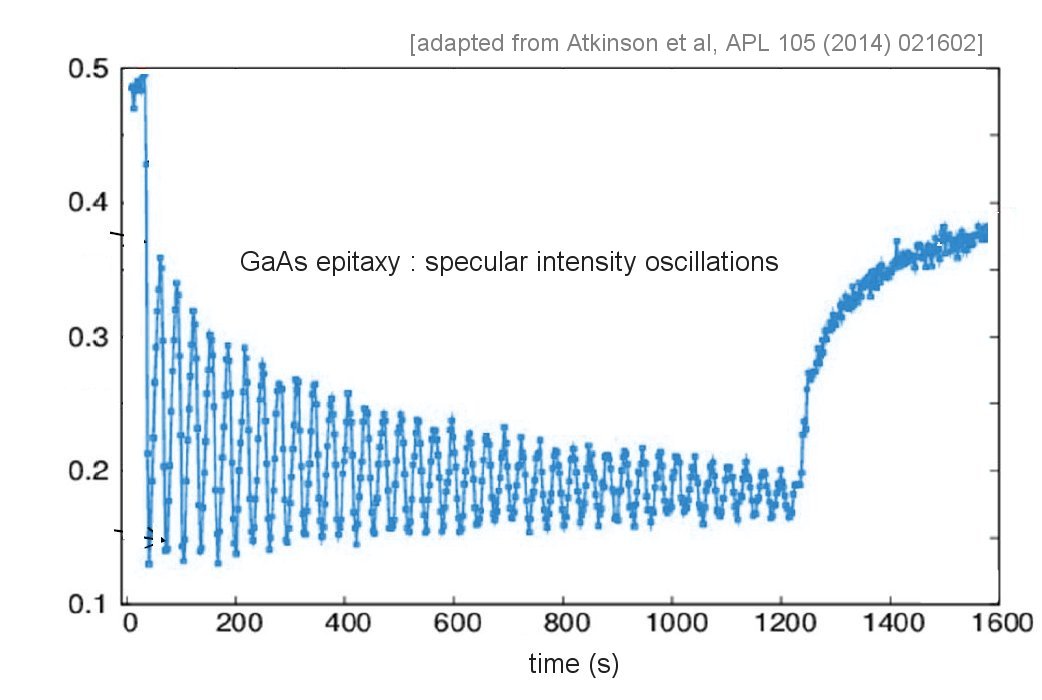

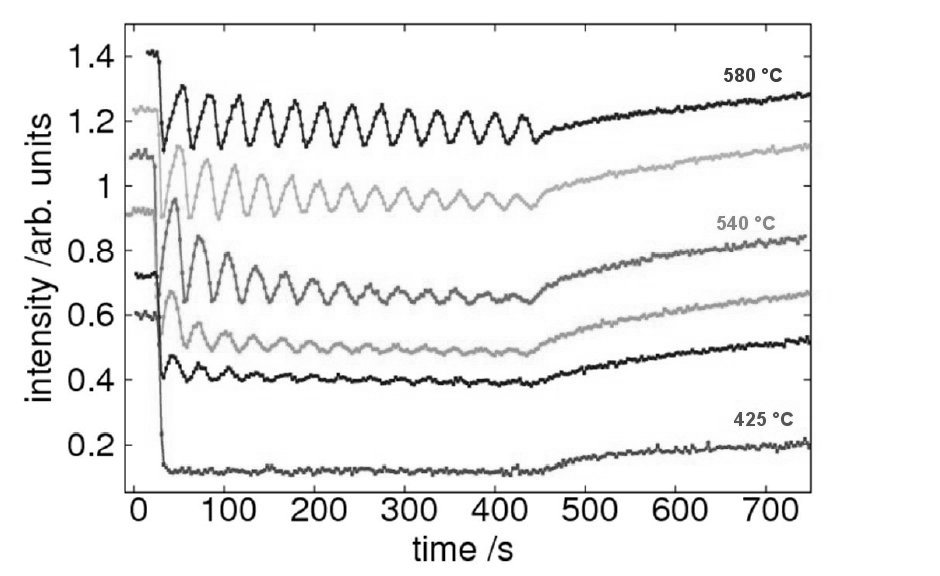

GIFAD intensity oscillations

Intensity evolution vs time of the GIFAD specular reflection during epitaxy of GaAs for increasing temperature of the substrate (from bottom to top).For high enough temperatures (T>500°C) the observed periodic oscillations evidence a layer by layer growth mode with increasing roughness when the thickness increases. The period of oscillations gives the time of completion of 1 monolayer of GaAs. It may be noted that with GIFAD all diffraction orders oscillate with the same phase whatever the incident angle which makes significant difference with RHEED. [ from Atkinson et al, APL 105 021602 (2014)]

- H.Kehmliche,P. Roncin et al – APL 95 (2009)

- M. Debiossac(2014) – PhD manuscipt :https://tel.archives-ouvertes.fr/tel-01128981

- Atkinson P. et al, APL 105 021602 (2014)

- Momeni A et al – J. Phys. Chem. Lett.9 (2018) 908